The devices responsible for moving specific types of load in industrial settings under strictly controlled circumstances and previously set parameters, are called motion control systems. They’re flexible, cost-efficient and highly effective devices which can be used in a wide range of industrial applications, ranging in power capacity, speed, cost and level of precision.

In a lot of cases, motion control systems are a great solution for applications with a high demand in terms of separating elements, product positioning and applications that require rapid starting, immediate stopping and quick gear shifting motions. Typical industrial motion control systems consist of several components, so let’s take a look at them.

Contents

Application Software

The purpose of the application software is to control the target positions and manage the motion control profiles.

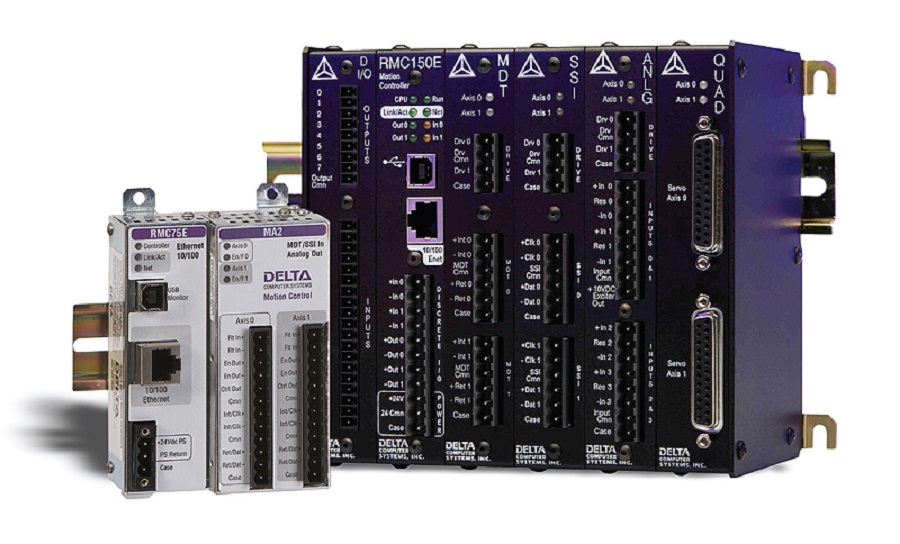

Motion Controllers

This component is the most crucial part of the motion control system. The motion controllers’ role in the operation of the system is to clear the path the motor needs to follow by reading the already determined motion profiles and target positions. Motion controllers react to all the changes spotted in the outer environment of the machine.

Amplifier/Drive

The amplifier/drive takes instructions from the motion controller and generates the needed amount of power necessary for driving the motor. Drives/amplifiers receive low energy reference signals from the motion controller and transform them into higher energy power signals.

Motor

The motor receives the power generated from the amplifier and transforms is into mechanical energy which is then transformed into the torque responsible for moving the load to the determined position. Motors can be single or three phased and the difference between them is the power density, power capacity, ease-of-use and maintenance.

Position Feedback Device

Also known as a position sensor, this is not an essential component in all motion control systems and is vital for servo motors only.

Other Mechanical Elements

Mechanical elements, such as special actuators, linear slides and robotic arms are the components which use the torque generated from the motor and ensure a flawless operation from industrial machines.

Motion control systems are a vital part of CNC machine tools and robotics. However, in these instances they perform more complex roles than when used with more specialized machines, which is often times referred as general motion control. These systems find wide application in the printing, packaging, semiconductor production, textile and assembly industries. They encompass every technology related to the movement of objects and cover every motion system, from micro-sized systems to micro sim systems such as a space platform.