Technologies first developed for the aerospace and military sectors have produced valuable data. Particularly in the field of thermal management, and the detrimental effects that excessive heat has on structural and engine vitals. Lessons learnt here have paved the way for countless products used in many everyday applications. One major area is maintaining optimal heat levels in vehicles.

Contents

What are Heat Shields?

Heat shields are solutions that resolve excess heat radiated from hot engine parts. This includes areas like the engine block, the exhaust manifolds, the transmission, and in cars fitted with turbos, the turbine and compressor. High temperatures generated here can have damaging effects on surrounding parts that are not designed to such extremes. Containing radiant heat is vital in maintaining a longer-lasting engine, optimal performance figures and general driver comfort.

Three products widely used today are adhesive heat barriers, heat shielding metal sheeting, and exhaust wraps. Adhesive heat barriers are steadily replacing traditional aluminium sheeting.

Adhesive Heat Shields

Adhesive heat shields are lightweight, easily applied flexible foils that shield engine components and underbody parts from high temperatures. They are used on the parts with high working temperatures and can be applied to surrounding areas to maintain optimal performance and working temperature levels.

Materials and Properties

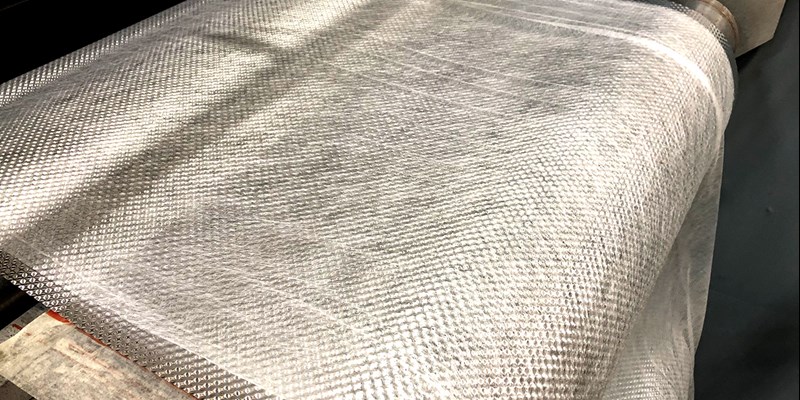

Adhesive heat barriers, or peel-and-stick heat shields, are composite foils consisting of high heat-conducting metals like silver, copper, or aluminium in the outer layers, a heat-resistant fibreglass and polyester core, and an adhesive lining. This combination makes for a foil that easily sticks to any engine parts that get really hot. Irregular surfaces, curves, protruding bolts or mounts are no issue here. The foil flexes and moulds into any shape needed. High-quality adhesives are not affected by changes in temperatures, nor expanding and shrinking metal parts.

Adhesive heat barriers come in several thicknesses to appropriately contain radiant heat. Thinner foils are used on parts that don’t generate high temperatures, but which may be indirectly damaged from other heat sources. Fluid lines and hoses, batteries, floor pans, firewalls, hood linings, steering parts and rubber mounts can all be shielded. Here adhesive heat barriers with 0.05mm out layers are adequate to contain temperatures up to 250°C. For flatter surfaces, and parts producing higher temperatures, a thicker outer layer of 0.25mm will do the job better.

Peel-and-stick heat shields are built to last. They not only contain extreme thermal forces, but also have high tensile strength, and don’t tear once applied. Rolls come in different sizes depending on the area or parts that need shielding. They are all easily cut to shape and any excess material is easily removed.

Advantages Over Aluminium Sheets

Adhesive shields have several advantages over thicker aluminium sheets used for the same purpose. First, they are easier and quicker to apply. The pressure-sensitive adhesive conforms to any surface, meaning no additional connecting parts and a better fit. By comparison, the thick aluminium sheets previously need to be formed to the component shape, with consideration to mounting bolts or screws. And you’ll need to be very precise to get the best results. Next is the resistance to tear. Adhesive barriers don’t crack or deform easily, whereas sheeting can and will deform over time. This can lead to dislodging from the mounts and the heat source. And then there’s the guesswork if sheets are actually where they should be. You’ll hear unpleasant rattling when loosened sheets scrape against other engine parts. Lastly, prices of adhesive barriers are coming down due to simpler production and packaging, making them a more cost-effective solution.

With such qualities in mind, some vehicle manufacturers are readily using adhesive heat barriers in new passenger vehicles. New engines need to comply with stricter emissions targets, meaning more heat from turbocharged units. Pre-installed adhesive heat barriers used here keep all parts within the optimal working range.

Besides production cars, adhesive heat shields are widely used in performance track vehicles with high power output. With cars stripped down to the minimum legal weight, lightweight adhesive foils form protective barriers, shielding the driver, the engine and the transmission. Notable examples include cars in the NASCAR and Australian Supercars Championship.

Other Heat Shield Products

Adhesive heat barriers, and to a lesser extent aluminium heat sheets, are used mostly in the engine bay and transmission. For exhausts, there is exhaust wrap to provide for better exhaust flow. And for cooler hoods and no chipped paint, hood liners are the best insulative solution. All products can be combined to provide the best performance results, while also protecting parts from overheating and causing further engine damage. Driver comfort is also important in this aspect. If you suspect higher temperatures in the footwells, it’s time for a checkup.

Buying Heat Shields

Peel-and-stick heat barriers, aluminium heat sheeting, exhaust wraps and hood liners are sold by tuners and specialised engine maintenance stores. When buying adhesive barriers, you have the option of different sized foils, both in overall area and thickness. Where adhesive barriers aren’t suitable, then go for aluminium sheeting. Prices are reasonable for the benefits these products offer.